HMI

“Human-Machine Interface”

The touchscreen interface operators use to control and monitor machines.

The touchscreen interface operators use to control and monitor machines.

EXPERIENCE

Midwest Engineered Systems

August 2024 – January 2025

GETTING TO KNOW THE COMPANY

MWES is an industrial automation and robotics integration company specialized in designing, building, integrating and supporting custom systems for manufacturers.

Custom projects mean custom interfaces for users to interact, interpret and gather data from machines. I contributed to these interfaces where UX/UI has real operational consequences.

Note: Due to an ongoing NDA with MWES, client names are undisclosed.

UX/UI SKILLSET’S LEVERAGED

Locations

Years

Systems

Locations in Pewaukee, WI

Years in the Industrial Automation Market

Systems Built

GETTING TO KNOW THE PROCESS

“Human-Machine Interface”

The touchscreen interface operators use to control and monitor machines.

The touchscreen interface operators use to control and monitor machines.

“Programmable Logic Controller”

The “brain” of the system, running the machine’s logic and sending real-time data to the HMI.

The “brain” of the system, running the machine’s logic and sending real-time data to the HMI.

A group of machines and robots working together on a specific task (e.g., welding or assembly), coordinated through PLCs and displayed on HMIs.

A group of machines and robots working together on a specific task (e.g., welding or assembly), coordinated through PLCs and displayed on HMIs.

HANDS ON EXPERIENCE

Worked on cross-disciplinary teams to design HMIs for custom industrial automation projects.

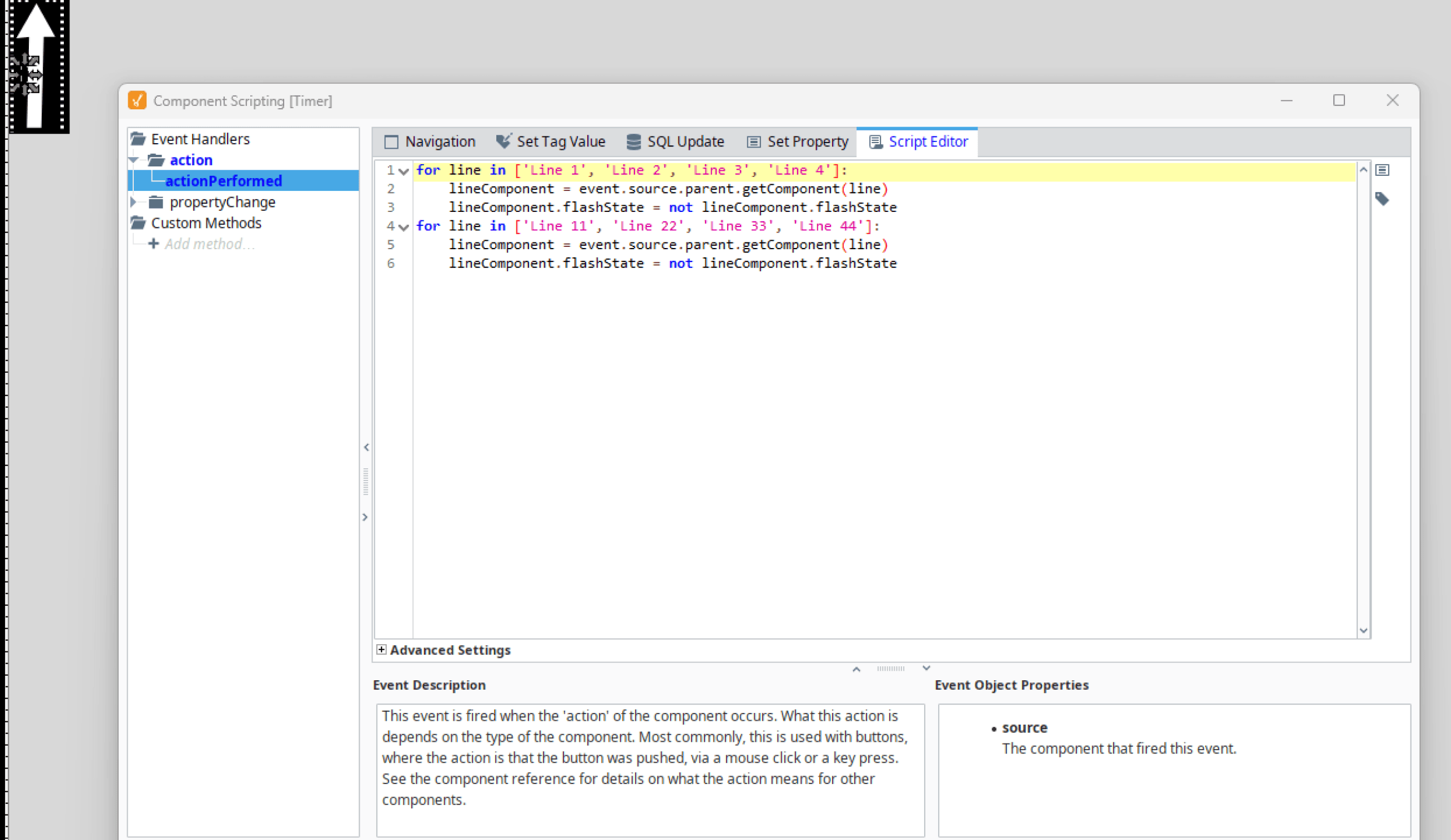

Troubleshooted HMI programming in Ignition Designer to ensure a seamless UI experience.

Designed an end-to-end HMI application in FactoryTalk View SE and deployed to an Allen-Bradley PanelView 5000.

Went off-site to help troubleshoot remote viewing via Ewon devices for a customer.

Hands-on PLC hardware + logic; programmed with Studio 5000 and implemented PLC logic.

Balanced usability, efficiency, design, and safety in complex industrial systems.

PROJECT 1

PROJECT 1

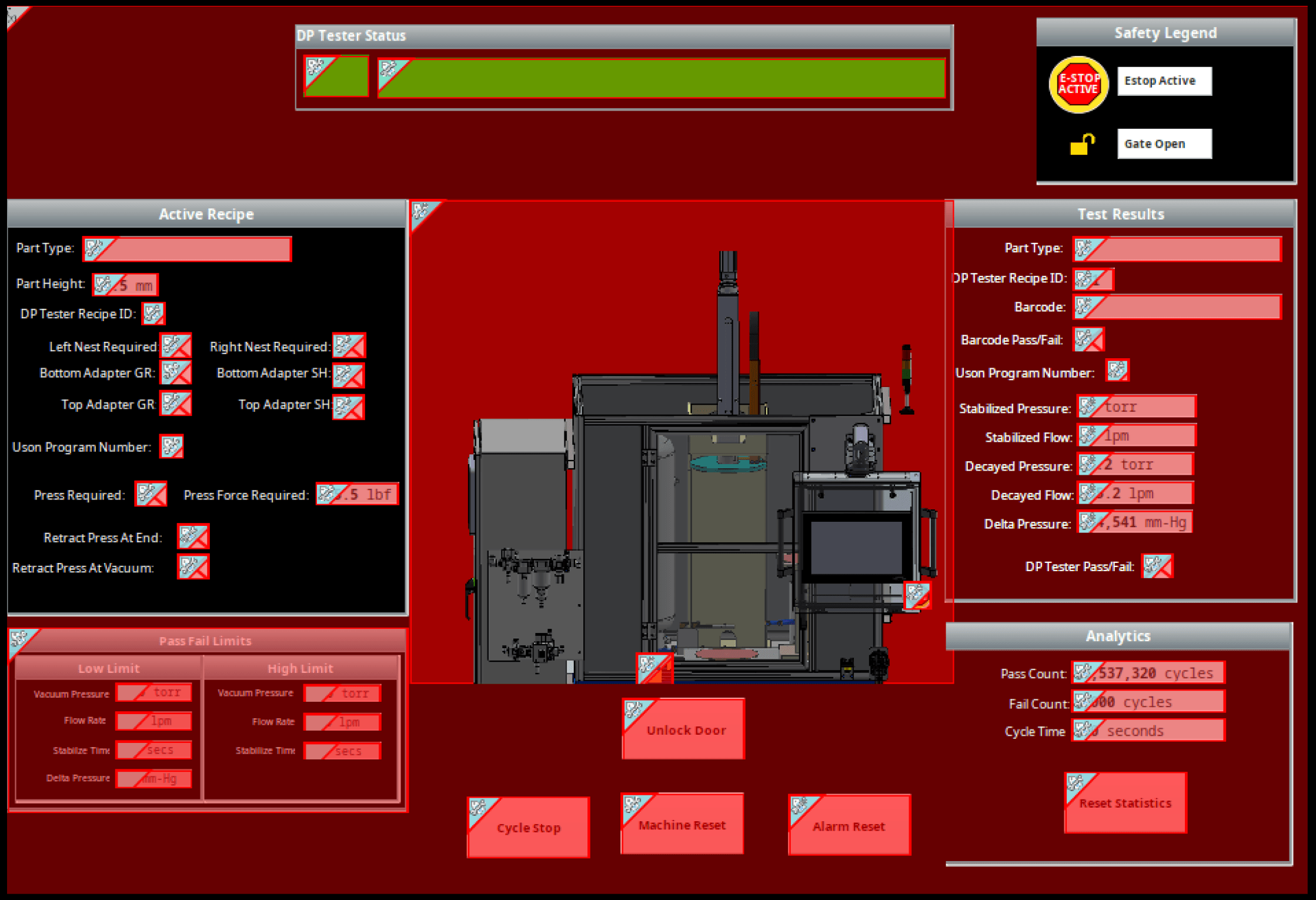

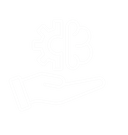

Image of DP Machine Status Screen — (red shown due to app being disconnected when saved)

Joined during testing to address usability issues in an Ignition HMI application. Ensured 11 screens were accurate and intuitive using Ignition logic, Python scripting, and PLC binding.

Resulting HMI improved trust and efficiency via accurate data, better spacing, and clearer inputs, supporting a smoother handoff and demonstrating how interface detail impacts factory-floor usability.

PROJECT 2

PROJECT 2

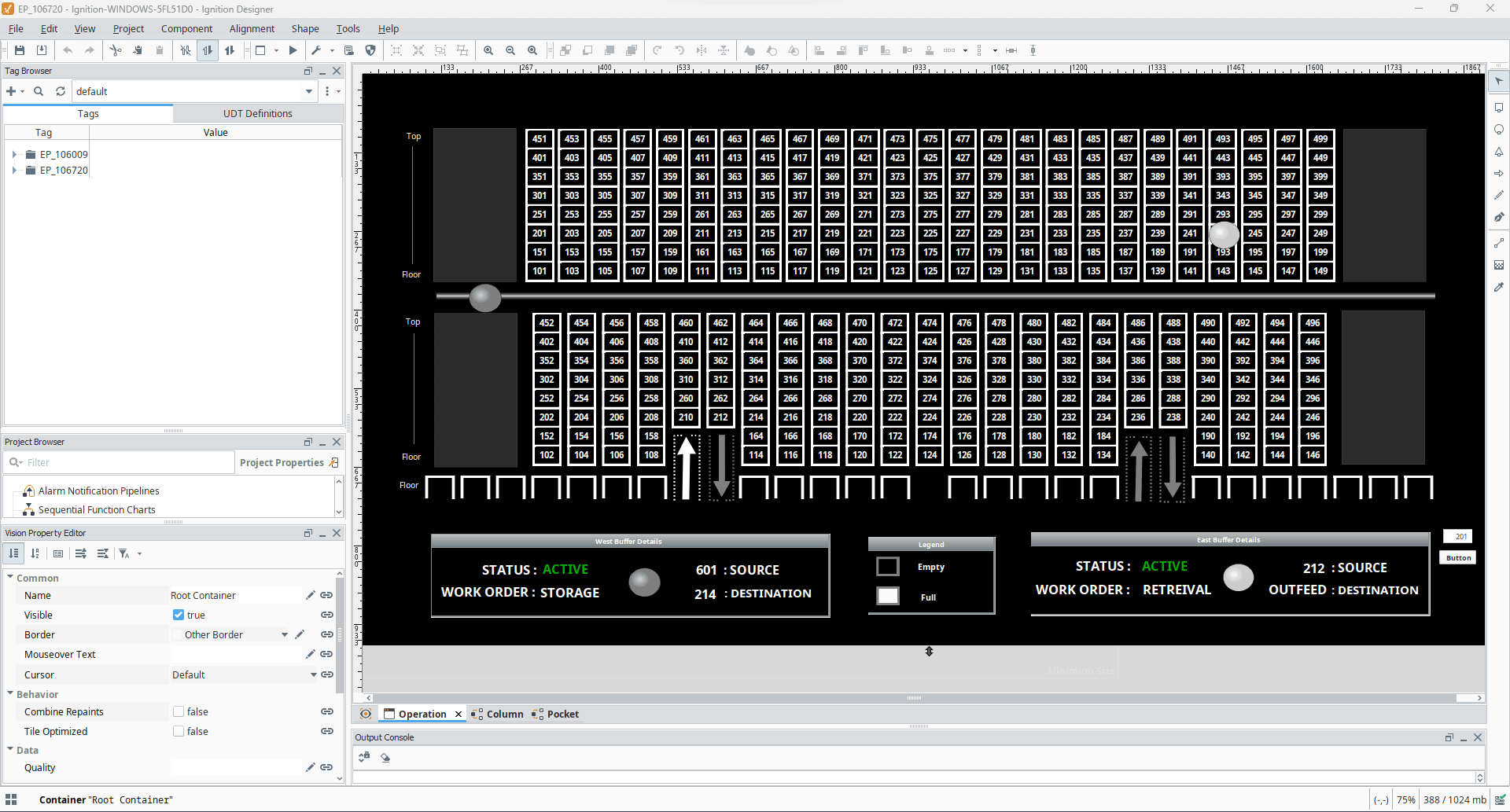

Image of DP Machine Status Screen — red shown due to app being disconnected when saved

Image of DP Machine Status Screen — red shown due to app being disconnected when saved

Designed an overview screen for an Automated Storage & Retrieval System (ASRS) in Ignition. Operators get a clear visual of slots, crane location, activity, and infeed/outfeed stations.

Grew HMI design skills in Ignition, especially Python scripting for logic/animation. Translated a physical system into an operator-friendly visualization.

PROJECT 3

PROJECT 3

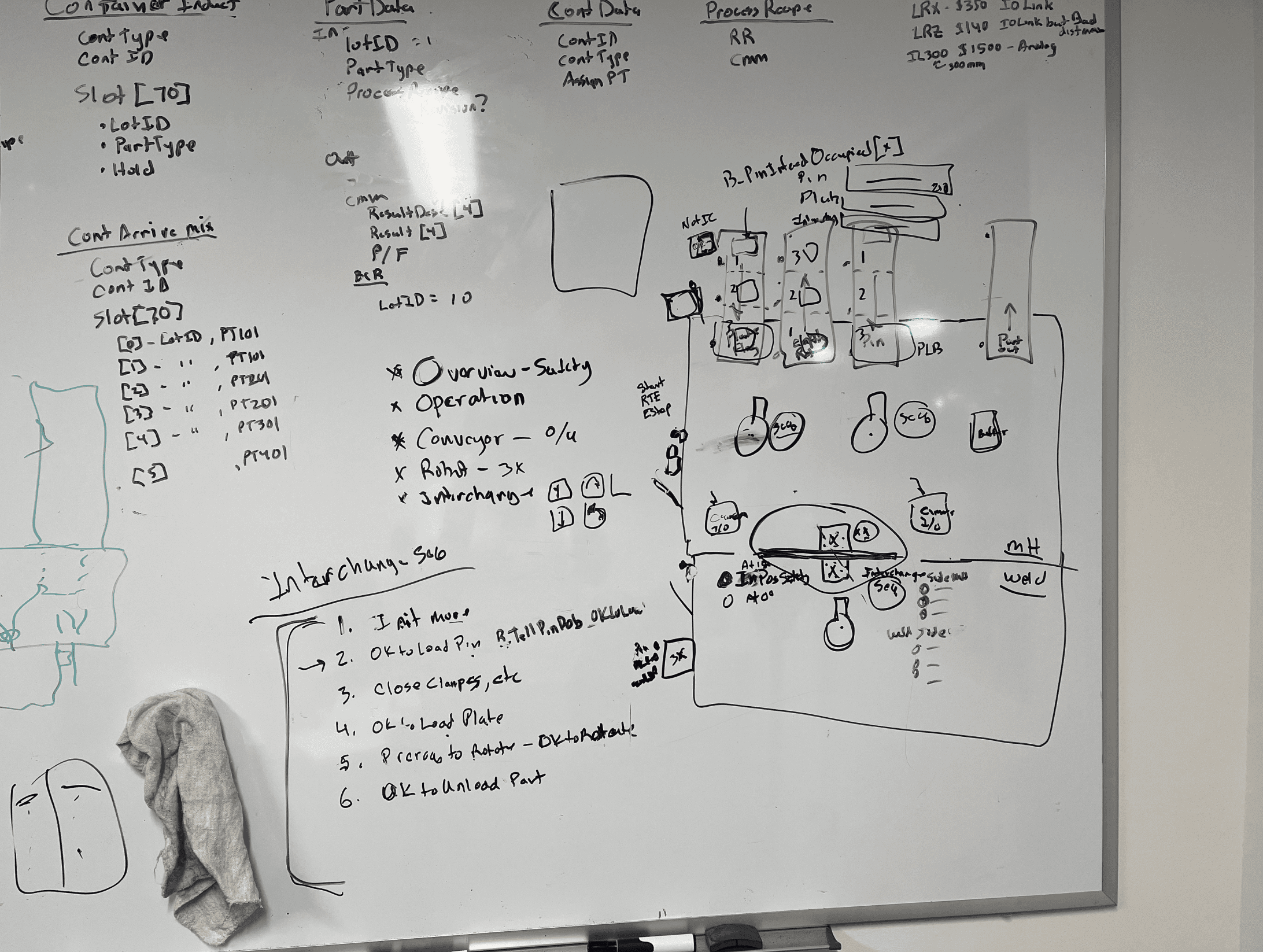

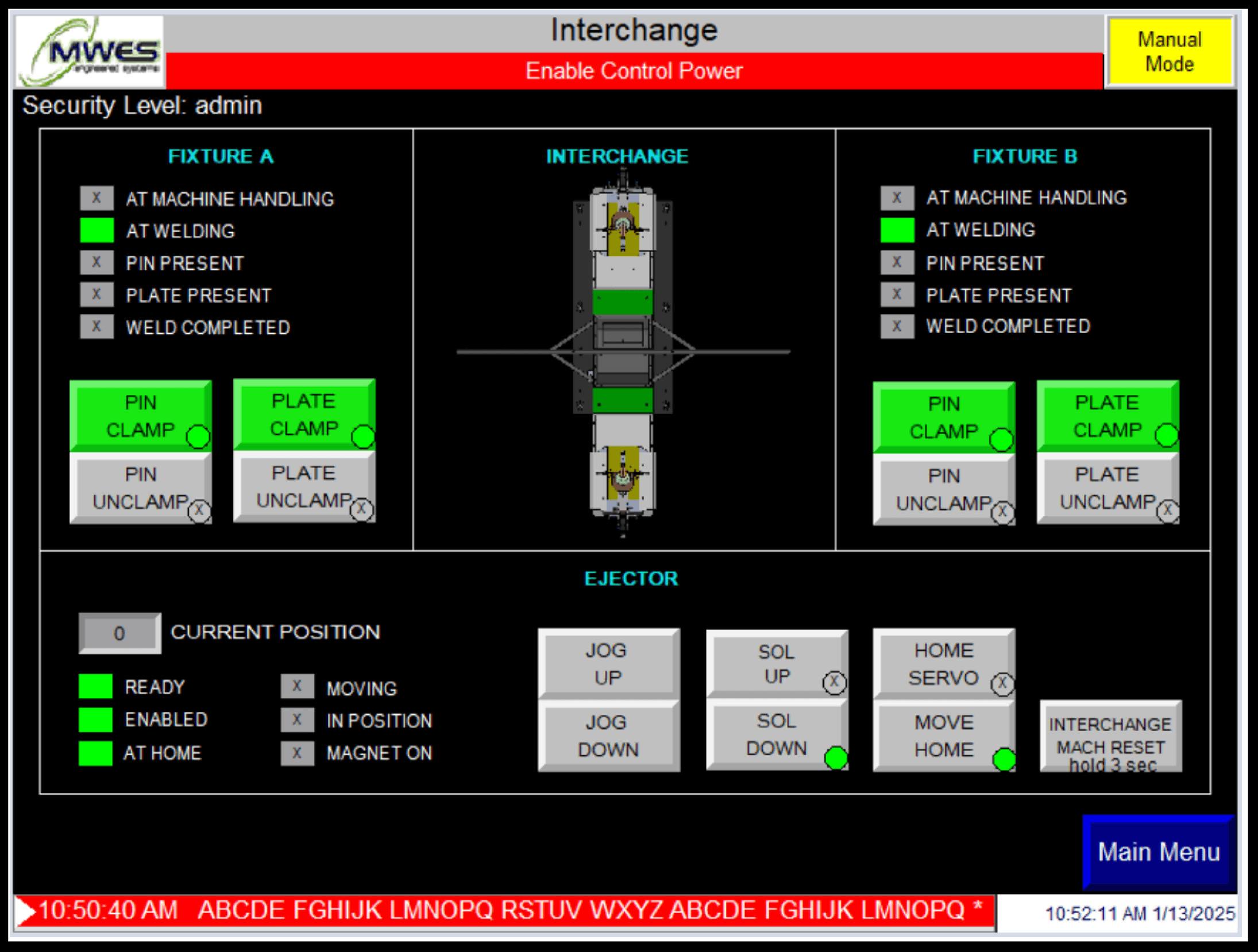

Brainstorming sessions with Controls Engineer Manager on layout and overview functionality.

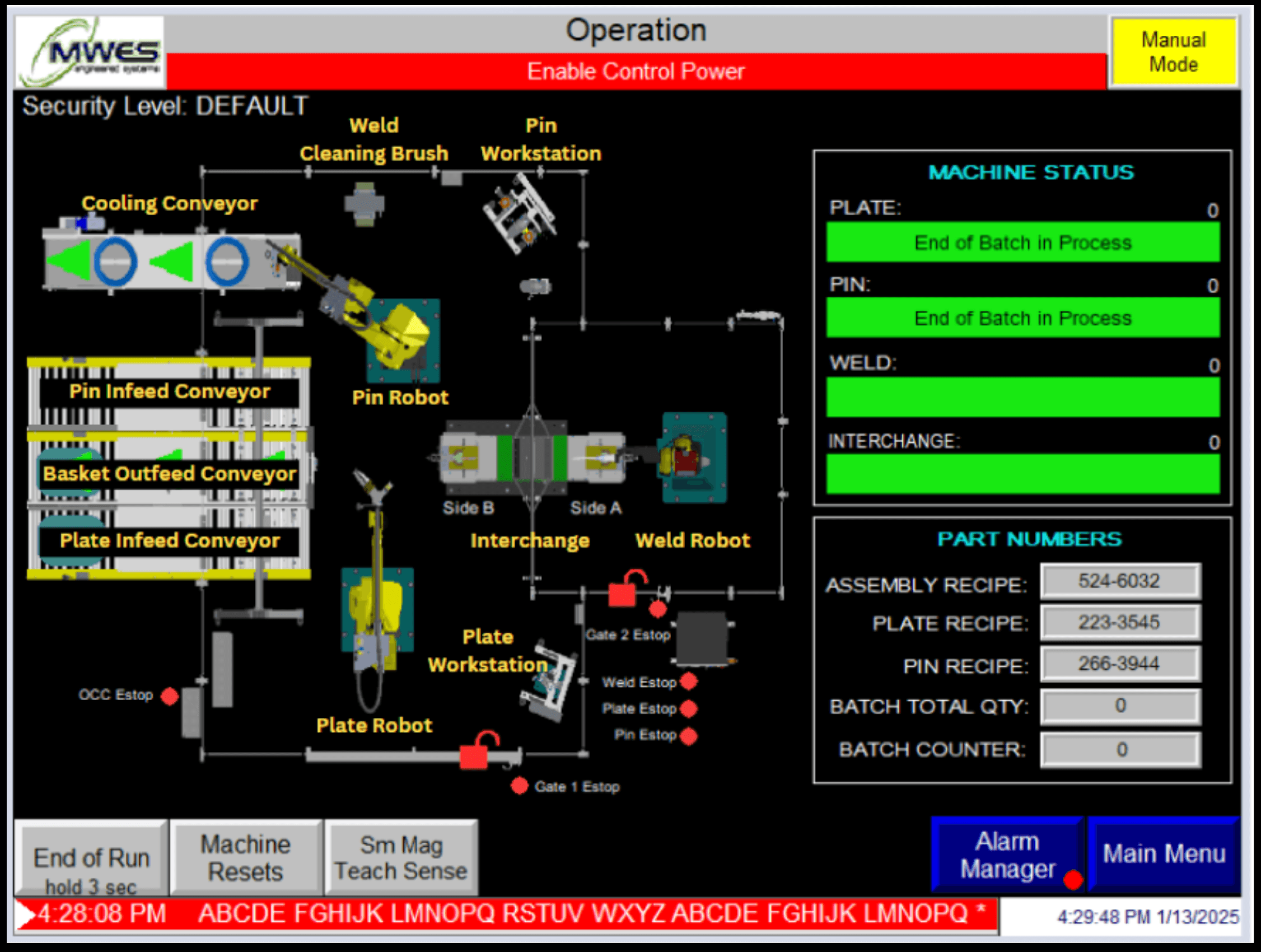

I designed and implemented a complete HMI application in FactoryTalk View SE for a robotic welding and assembly cell. Operators can control cell functions and see real-time status, part flow, and alarms, all within an interface aligned with the company’s design system. The role blended UI design, user flows, and interaction logic with technical implementation.

Final rendition of overview screen.

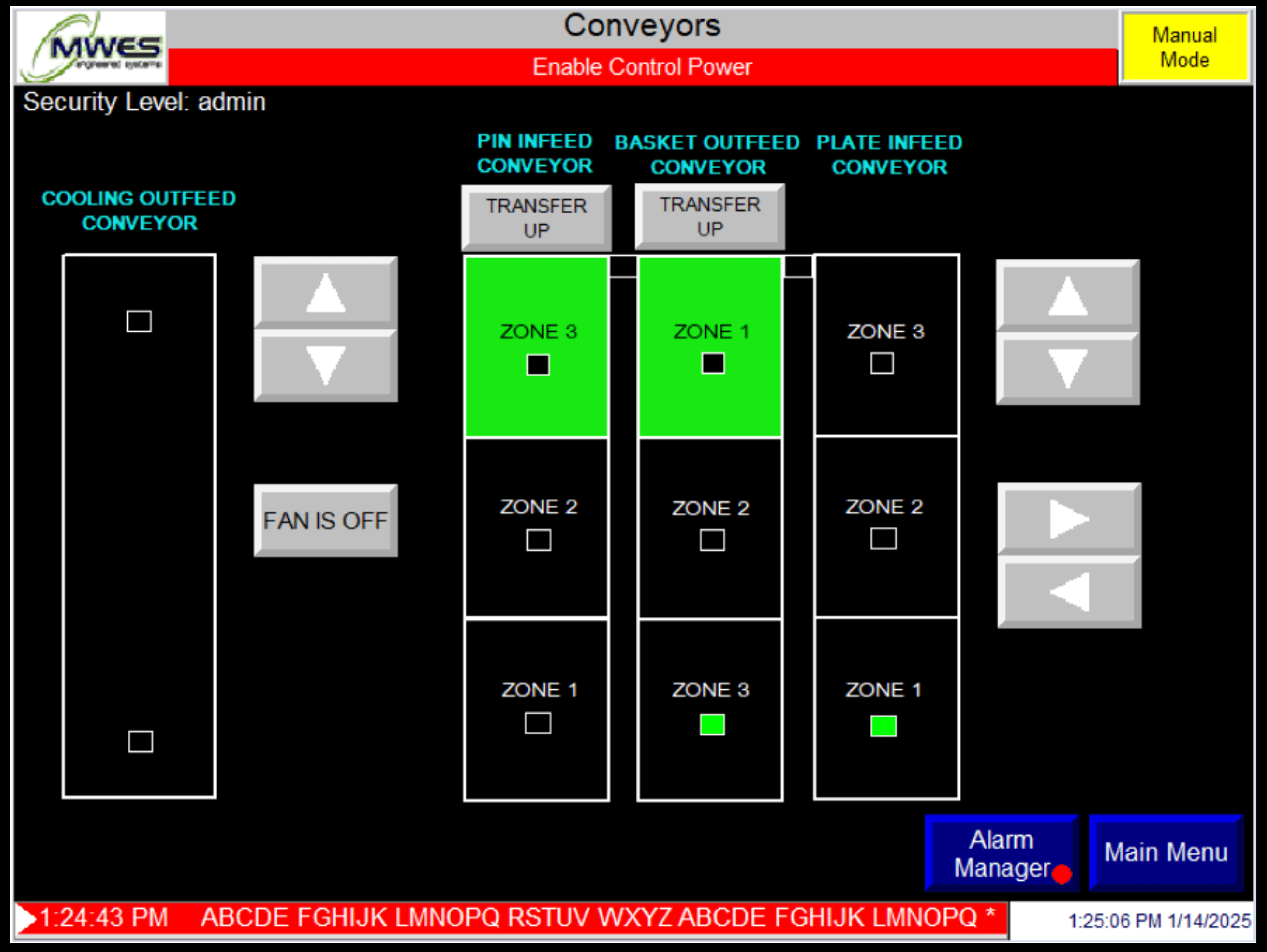

One of the biggest challenges was designing the conveyor control screen for maintenance and operation modes. Operators needed a clear way to test ten conveyor belts, each capable of moving in multiple directions, while also monitoring occupancy.

I explored multiple iterations and landed on a simplified 2D layout:

The design balanced functionality with clarity so operators could quickly test, diagnose, and monitor conveyors without confusion.

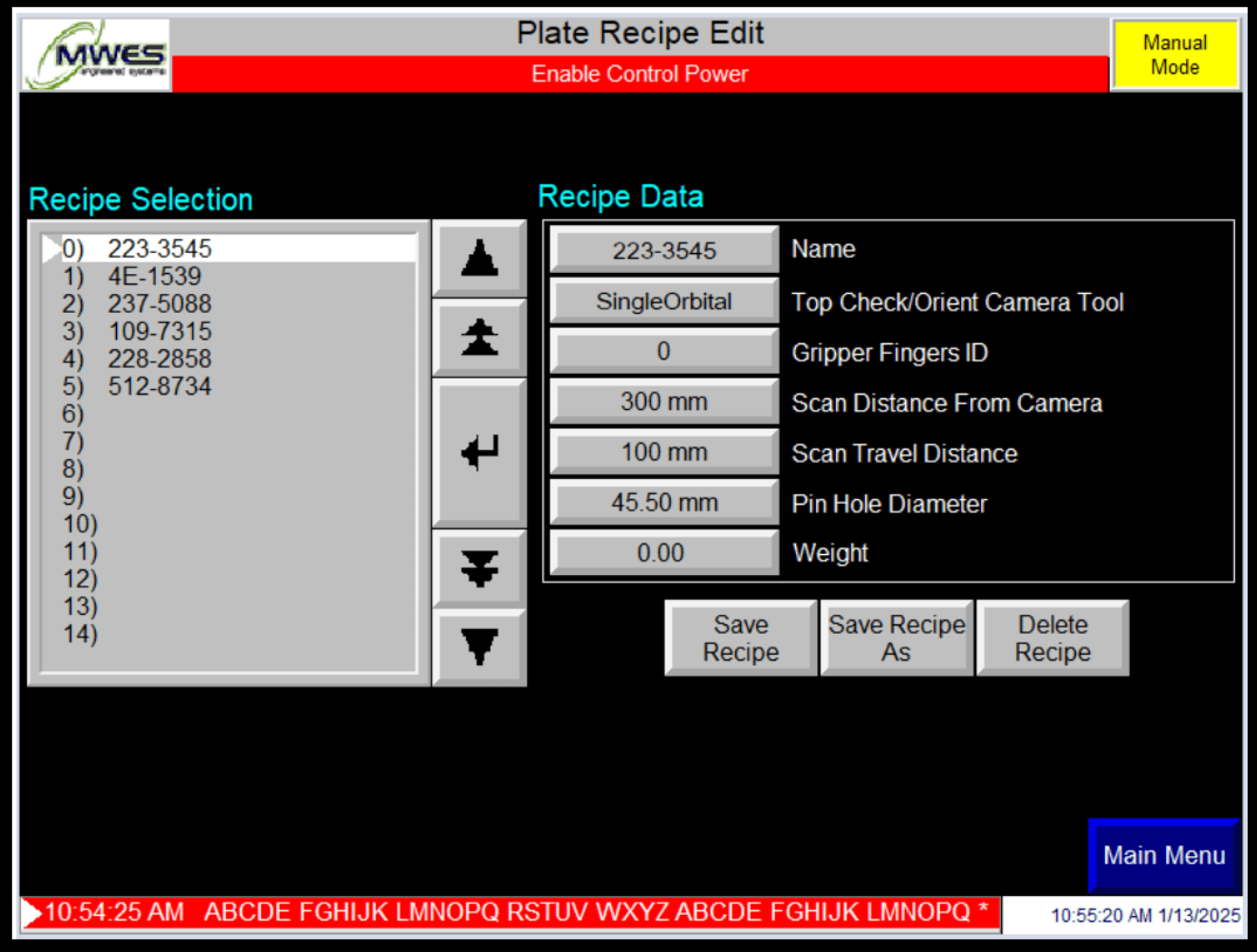

A major challenge in this project was learning and creating PLC logic to support the recipe functionality. I built logic that allowed operators to save, edit, and delete both pin and plate recipes, then ensured these updates were reflected in the HMI application. I learned how to read electrical schematics to trace connections and troubleshoot logic that wasn’t working as expected. After finishing PLC logic, I integrated it with the HMI screens so operators could seamlessly manage recipes through the interface—requiring technical accuracy and a strong understanding of operator workflows.

This project let me bridge UI design principles with industrial automation. Following HMI design guidelines reinforced how consistency and clarity are critical for operators. Uploading and organizing the tag database, then binding PLC tags to on-screen components, strengthened my understanding of how the HMI layer connects to real machine behavior. I also created my own PLC logic for searching, saving, and deleting recipes, deepening my grasp of accurate process control. Finally, documenting the application for the customer’s operation manual improved my ability to explain complex systems in a clear, actionable way.

OUTCOME

Jumping into the automation industry, with a full-stack web development background, was a daunting start met with immense reward. I love learning and being able to make meaningful contributions through problem solving and design thinking.

One of the biggest challenges of this project was bridging the gap between design and development. On the surface, creating HMI screens might seem like a purely technical task, but I quickly learned how deeply design decisions impact usability. Every choice from layout and spacing to how recipes were saved and displayed had to balance technical accuracy with operator clarity.

At times, I dove into PLC logic and electrical schematics to ensure functionality matched the interface, pushing me beyond “designing screens” into truly integrating design with development. This process was rewarding and eye-opening: it showed how impactful good interface design is in complex, high-stakes environments, and it ultimately fueled my decision to pivot my career focus from software engineering toward UX/UI design.